The future of 3D-printed stethoscopes is changing healthcare by making medical tools more affordable and easier to access. With just a 3D printer and low-cost materials, doctors can create stethoscopes that work just as well as traditional ones. This innovation is especially helpful in remote or low-income areas where medical supplies are scarce.

Let’s explore how these stethoscopes work, their benefits, potential risks, and what they mean for the future of medicine.

Why Are 3D-Printed Stethoscopes a Big Deal?

Traditional stethoscopes can cost anywhere from $50 to over $200. However, a 3D-printed stethoscope can be made for less than $5. This makes it possible for doctors, nurses, and even students to access high-quality tools without spending too much money.

Benefits:

- Affordable: Costs a fraction of traditional stethoscopes.

- Easy to Make: A stethoscope can be 3D-printed in just a few hours.

- Customizable: You can adjust the design to fit specific needs, like for children or people with hearing difficulties.

- Accessible: Doctors in rural areas can print their tools instead of waiting for deliveries.

According to a study by researchers at the University of Toronto, these stethoscopes are just as effective as high-end brands. They provide clear sound quality and can even be sterilized for reuse.

How 3D Printing Is Transforming Medicine?

You may wonder, is 3D printing the future? The answer is yes! In addition to stethoscopes, 3D printing is used to create prosthetic limbs, dental implants, and even artificial organs. It’s already making medical care faster, cheaper, and more efficient.

Where Does 3D Printing Stand in Medicine?

- Rapid Prototyping: Doctors can create and test new tools in a matter of hours.

- Personalized Care: 3D printers allow for customized medical devices, like hearing aids or surgical guides.

- Global Impact: In countries with limited healthcare resources, 3D printing offers lifesaving solutions at low costs.

This technology is not only affordable but also sustainable. It reduces waste by using only the materials needed to create a tool.

What Are the Risks of 3D Printing in Medicine?

Even though 3D printing is exciting, it comes with challenges. For example, some materials used in 3D printing release harmful fumes when melted. This raises questions about the health risks of 3D printing, especially for people working with printers for long hours.

Common Dangers:

- Toxic Emissions: When heated, materials like PLA (polylactic acid) can release tiny particles into the air. Without proper ventilation, this could affect your lungs.

- Material Weakness: Some 3D-printed tools may not be as strong or durable as factory-made versions.

- Improper Use: Using low-quality printers or incorrect materials can result in faulty tools, which could impact patient safety.

To reduce these risks, hospitals and clinics should use high-quality 3D printers and medical-grade materials. Proper ventilation and safety training can also protect workers.

A Closer Look at PLA and Its Health Risks

One popular material for 3D printing is PLA, a biodegradable plastic. It’s affordable and easy to use, but it has its limitations. While it is generally safe, the health risks of 3D printing PLA include:

- Fumes are released during printing, which can irritate your throat and eyes.

- Weakness under high heat can make PLA-based tools less durable.

Doctors and researchers are working on ways to make PLA stronger and safer for medical use. This could open the door for more 3D-printed tools in the future.

The Role of 3D-Printed Stethoscopes in Telemedicine

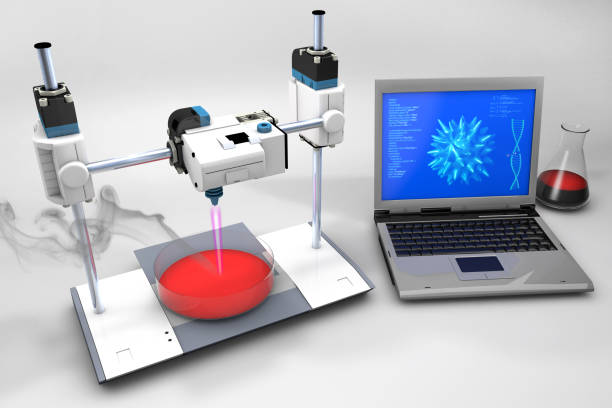

The future of stethoscopes is not just in their affordability but also in their ability to connect with modern technology. Some 3D-printed stethoscopes now include stereoscopic 3D lighting projection. This allows doctors to examine patients remotely, making it a valuable tool for telemedicine.

Benefits:

- Remote Monitoring: Patients in rural areas can have their heartbeats checked by doctors miles away.

- Data Sharing: Doctors can record and analyze sounds for better diagnoses.

- Improved Access: Telemedicine tools bring healthcare to places that lack medical professionals.

This combination of 3D printing and telemedicine is a game-changer for global health.

How Do 3D-Printed Stethoscopes Compare to Traditional Ones?

| Feature | Traditional Stethoscopes | 3D-Printed Stethoscopes |

| Cost | $50–$200+ | $3–$5 |

| Customization | Limited | High |

| Time to Produce | Factory-made (weeks) | On-demand (hours) |

| Durability | High | Depends on the material used |

| Global Accessibility | Limited in rural areas | Easy with a 3D printer |

While traditional stethoscopes are durable and reliable, 3D-printed versions offer affordability and accessibility. They’re an excellent solution for areas with limited resources.

The Future of 3D-Printed Stethoscopes

The future of 3D-printed stethoscopes looks bright. As materials and printers improve, we can expect even better tools. Innovations like the connected stethoscope show how 3D printing can bridge gaps in healthcare. With proper safety measures, this technology could make high-quality medical tools available to everyone, everywhere.

Conclusion

The future of 3D-printed stethoscopes is filled with promise. They are affordable, customizable, and accessible, offering solutions to many global healthcare challenges. While there are some risks, advancements in technology and safety practices continue to improve their reliability.

As 3D printing becomes more common, it will likely play an even bigger role in medicine. From stethoscopes to surgical tools, this technology is changing how doctors and patients interact. The future of medicine is here—and it’s being built layer by layer.